El Jason

Well-known member

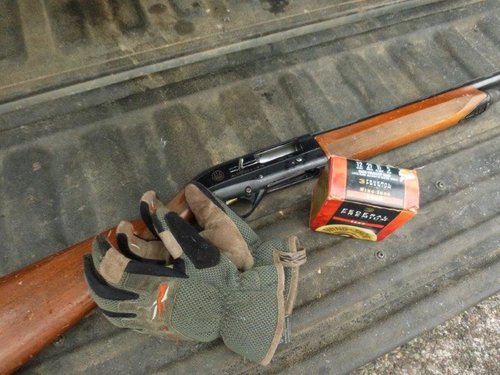

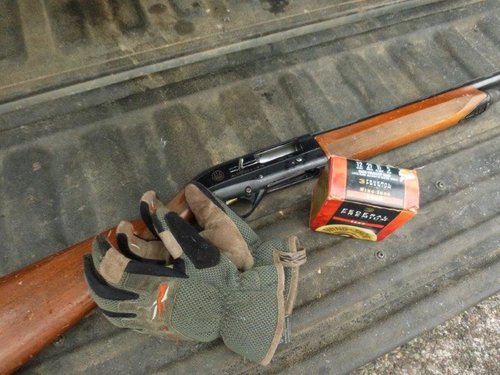

Is not an easy one. My Beretta AL 391 has seen some tough love for sure, from the duck marshes to the basalt cliffs of Hell's Canyon.

I took a few hard tumbles this year and decided that it was time to shed the ugly factory varnish.

A few coats of Citristrip and we were down to this.

A couple of coats of oil and the checkering has been recut.

After a few more sandings.

The final product.

I took a few hard tumbles this year and decided that it was time to shed the ugly factory varnish.

A few coats of Citristrip and we were down to this.

A couple of coats of oil and the checkering has been recut.

After a few more sandings.

The final product.

Last edited by a moderator: