D

Deleted member 28227

Guest

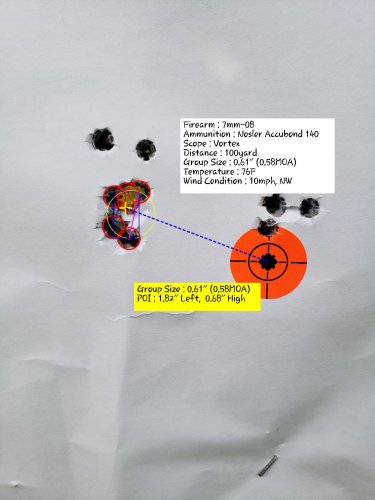

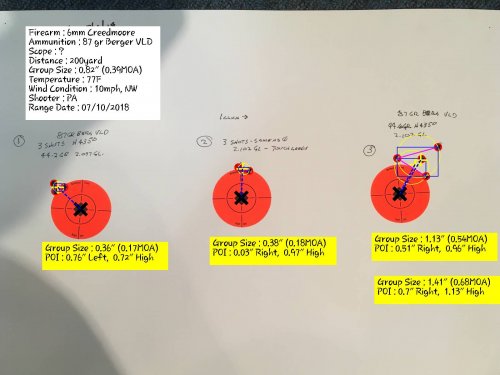

It will most likely have difficulty stabilizing. You quite possibly will shoot oblong holes. The min recommended twist rates are truly min. Particularly with the long for caliber bullets. Higher stability aids in terminal performance as well. I like my hunting rigs running closer to 2.0 sg if possible.

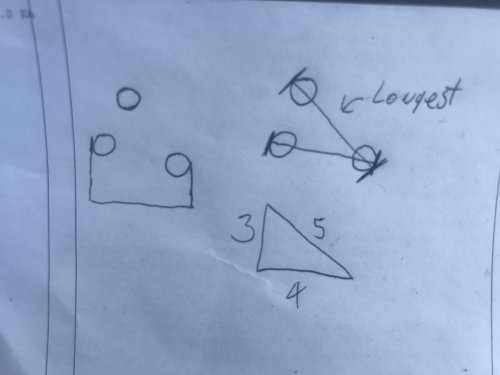

Why not just make all rifles 1 in 6 then... I've tried to googled twist rates and conceptually I get it but haven't seen examples of over or under twisting bullets + the down range effect.