Building a 4x4x8 hay transport trailer for a UTV.

I'm at the point of building the sleeves for the wheel spindles and have a load integrity question.

I want the load in front of the axle ---> towards the trailer tongue. A 3x3x8 &/or 4x4x8 bale of hay... 800 lbs - 1600 lbs.

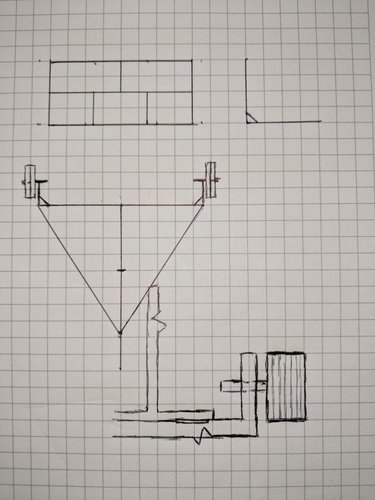

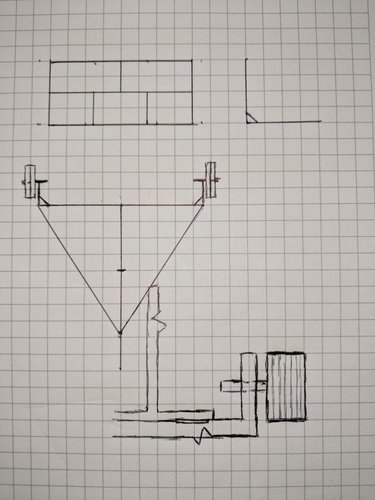

In the drawing, this is what I intend to build for axle/spindle location instead of running the wheels off the direct end of the square tubing which I know would be the most ideal however, to account for keeping the weight of the bale in front of the axle, I would like to modify the wheel location, as shown.

Intent for transport:

The forks and backing are hinged to the tube steel. A manual winch mounted to the front area of the trailer (towards tongue). The winch will pull the backer/forks to rest on a "T" platform mounted 4' from the steel junction. The bale will transport = the height of the center of the wheel location. It's hard to describe though I think you may have an understanding...

Basically, will the design to mount a short "axle" for the wheel spindles hold the integrity for transporting bales?

Steel used for trailer:

2x2" Square tubing .25 thickness - trailer build.

3" C Channel .25 thickness - trailer bracing & forks.

1x3" Tube .125 thickness - backer frame.

Wheel hub kit: 1250 lbs ea.

Tires: 225 75/R15

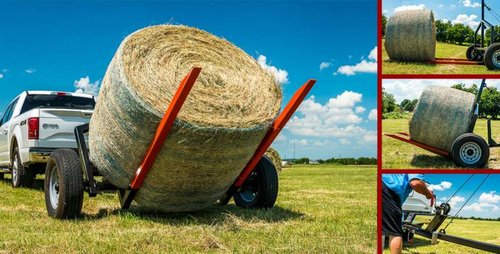

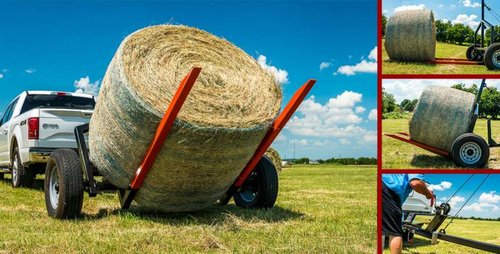

This is the general ideal: Credit for use of the picture - http://gobobpipe.com/poke-n-tote-hay-trailer.htm

Very basic drawing:

Build thus far - exclude the tires in this picture.

Pic of current tire selection, wheel hub assembly and spindle kits.

Thanks for your input. I know my design is a bit overkill for steel thickness, etc... kinda a tank build for a go-kart intent... but easy pull for a UTV. so the stronger the better... it's the wheel location and weight distribution that I want to make sure is good before proceeding further.

I'm at the point of building the sleeves for the wheel spindles and have a load integrity question.

I want the load in front of the axle ---> towards the trailer tongue. A 3x3x8 &/or 4x4x8 bale of hay... 800 lbs - 1600 lbs.

In the drawing, this is what I intend to build for axle/spindle location instead of running the wheels off the direct end of the square tubing which I know would be the most ideal however, to account for keeping the weight of the bale in front of the axle, I would like to modify the wheel location, as shown.

Intent for transport:

The forks and backing are hinged to the tube steel. A manual winch mounted to the front area of the trailer (towards tongue). The winch will pull the backer/forks to rest on a "T" platform mounted 4' from the steel junction. The bale will transport = the height of the center of the wheel location. It's hard to describe though I think you may have an understanding...

Basically, will the design to mount a short "axle" for the wheel spindles hold the integrity for transporting bales?

Steel used for trailer:

2x2" Square tubing .25 thickness - trailer build.

3" C Channel .25 thickness - trailer bracing & forks.

1x3" Tube .125 thickness - backer frame.

Wheel hub kit: 1250 lbs ea.

Tires: 225 75/R15

This is the general ideal: Credit for use of the picture - http://gobobpipe.com/poke-n-tote-hay-trailer.htm

Very basic drawing:

Build thus far - exclude the tires in this picture.

Pic of current tire selection, wheel hub assembly and spindle kits.

Thanks for your input. I know my design is a bit overkill for steel thickness, etc... kinda a tank build for a go-kart intent... but easy pull for a UTV. so the stronger the better... it's the wheel location and weight distribution that I want to make sure is good before proceeding further.