Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Metalworking Hunttalkers!

- Thread starter p_ham

- Start date

np307

Well-known member

np307

Well-known member

Big day today, went on my first solo service call. The tank we worked on a few weeks back needed a temperature probe put in so I cut a tee in and welded on a ferrule. Went pretty smooth.

Then back at the shop we started work on a table for one of the plants. Pretty happy with how my fillet welds turned out.

Then back at the shop we started work on a table for one of the plants. Pretty happy with how my fillet welds turned out.

np307

Well-known member

I’m the process of buying a new to me truck and the outrigger cylinders need to be rebuilt. Needed the truck for an emergency last minute when my chipper went down so I made a quick fix to hold the outriggers up on the road. Much safer and better than the ghetto fix the previous owner settled on. He had a rope system to the levers on top of the truck and running through the window. He would throw it in neutral and raise the outriggers mid drive. That’s not how I roll. This isn’t pretty but it’s safe and accomplished the goal. 11:30pm start time in pouring rain, I’ll take it…

Attachments

millerkiller77

Well-known member

Did you buy the truck from Fred G. Sanford? LolI’m the process of buying a new to me truck and the outrigger cylinders need to be rebuilt. Needed the truck for an emergency last minute when my chipper went down so I made a quick fix to hold the outriggers up on the road. Much safer and better than the ghetto fix the previous owner settled on. He had a rope system to the levers on top of the truck and running through the window. He would throw it in neutral and raise the outriggers mid drive. That’s not how I roll. This isn’t pretty but it’s safe and accomplished the goal. 11:30pm start time in pouring rain, I’ll take it…

In all seriousness, that patch up you did is just fine. When you get some down time, rebuild the cylinders. It's so simple, I've done hundreds of cylinder rebuilds in the field and in the shop.. it's part of owning equipment.

np307

Well-known member

Zach

Well-known member

np307

Well-known member

np307

Well-known member

Well we got very fortunate with the old lines lining up pretty well so we were able to get everything done today. 15.5 hours, don't have to come back tomorrow. 5 solo fits for me, quite a few welds in the whole deal. Only had one connection I had to re-fit and 2 welds I had to fix. The biggest section of tubing I had to fit up:

Redmt

Well-known member

One man elk hauling mission but with a trekking pole it could probably have multiple issues

**typo but to funny to edit. It will likely have issues because I am shooting from the hood here, in the dark.

Was going for multiple uses

np307

Well-known member

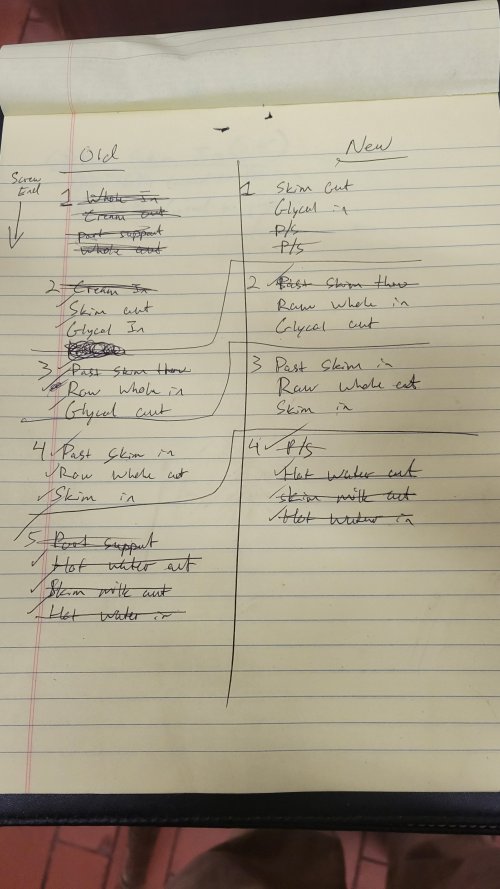

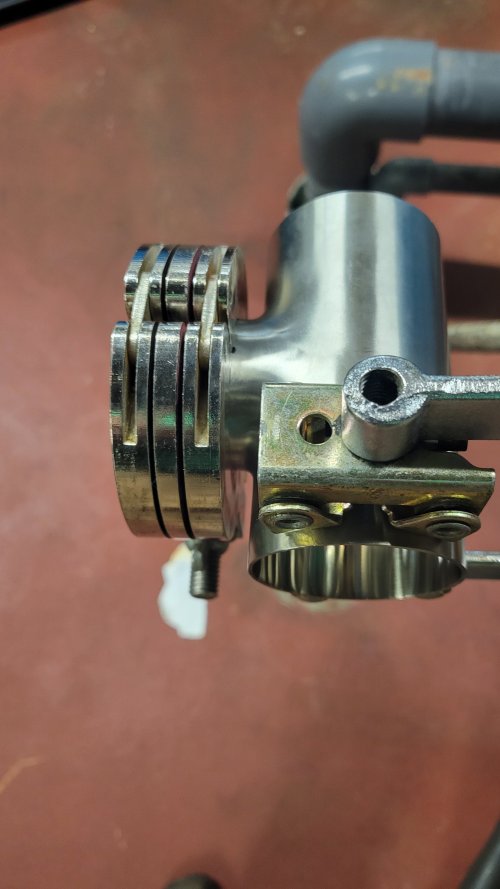

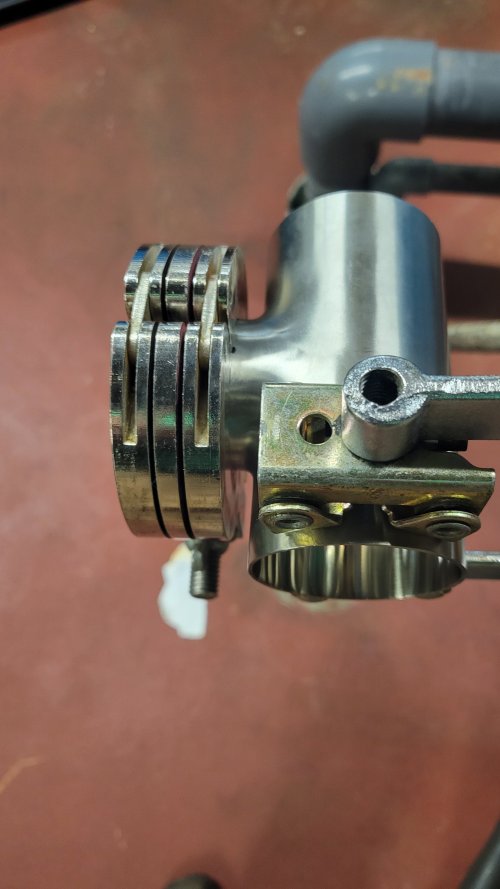

My list for today is just shop errands so I'll go ahead and post my weekly round-up. Had a platform come loose that was supposed to be secured in the ceiling which meant I had to climb up in the ceiling. That was a nightmare. I've been in several crawl spaces easier to navigate. Then we had a job cutting in some tees for conductivity sensors. Had to cut the tees back pretty far so that the sensor would be centered in the line. Pretty close shave.

Got the wheel in yesterday so I could add a little bit more to the cart. Had to shift the wheel placement around a bit and add some length to the handles in order to keep the wheel from hitting my heels. (I have long ass legs)

Now I’m just waiting for the axle and some removable sleeves to keep the tire/axle in place.

Getting excited. Gonna have to give @MtnElk a ride around the block when it’s all finished up to make sure it can hold a couple boned out 1/4s

Last edited:

Gerald Martin

Well-known member

- Joined

- Jul 3, 2009

- Messages

- 9,480

View attachment 289699View attachment 289700View attachment 289701View attachment 289702View attachment 289703View attachment 289704

Got the wheel in yesterday so I could add a little bit more to the cart. Had to shift the wheel placement around a bit and add some length to the handles in order to keep the wheel from hitting my heels. (I have long ass legs)

Now I’m just waiting for the axle and some removable sleeves to keep the tire/axle in place.

Getting excited. Gonna have to give @MtnElk a ride around the block when it’s all finished up to make sure it can hold a couple boned out 1/4s

Do you have a braking system on your cart? Two hundred pounds of elk meat builds up a lot of momentum on a downhill.

I found that out the hard way. When you are the front guy on a two person cart and gravity overcomes the friction of a brake and the cart tries to center you between the handles and a tree it gets pretty exciting….

I do not. Will have to figure something out for that I guess. The hunt I’m designing this for is a lot of miles but mellow terrain though. Definitely not an every hunt kind of cartDo you have a braking system on your cart? Two hundred pounds of elk meat builds up a lot of momentum on a downhill.

I found that out the hard way. When you are the front guy on a two person cart and gravity overcomes the friction of a brake and the cart tries to center you between the handles and a tree it gets pretty exciting….

D

Deleted member 52098

Guest

That’s what bigger friends are for… to test weight limits haView attachment 289699View attachment 289700View attachment 289701View attachment 289702View attachment 289703View attachment 289704

Got the wheel in yesterday so I could add a little bit more to the cart. Had to shift the wheel placement around a bit and add some length to the handles in order to keep the wheel from hitting my heels. (I have long ass legs)

Now I’m just waiting for the axle and some removable sleeves to keep the tire/axle in place.

Getting excited. Gonna have to give @MtnElk a ride around the block when it’s all finished up to make sure it can hold a couple boned out 1/4s

Similar threads

- Replies

- 0

- Views

- 365

- Replies

- 37

- Views

- 5K