Apologies if this has been posted before but I searched and didn't see much on it. Figured I'd post my process in case others find it helpful. Note this is just my process and what seemed to work for me but I'm sure there are a million ways to do this.

First the results. I have a Tikka 308 that was not shooting at the level I expect, and determined that copper fouling seemed to be the culprit. Dyna-tek bore coat was commonly recommended to address that issue, and after testing this weekend I do believe it helps significantly. First time out of the box at the range, I started getting fliers pretty frequently, after maybe 3 or 4 shots, shooting nosler etip lead free ammo. Yesterday was my first day at the range post bore coating and first tip, don't forget to put your bolt back into your rifle after allowing the drying period to finish or you might have to drive all the way home and all the way back before firing a shot.... not that I would know about that....

Anyways, I fired off 10 rounds per the instructions, to cure the compound in the barrel and noticed a difference pretty quickly. The very first shot was a bit wild, upper right corner of the target but every shot after that was dead nuts, about an 3 inches high at 100 yards and all nine rounds could easily be covered by a playing card. Which.. for those that shoot 10 round groups the size of a quarter at 100 yards might not be impressed, but it impressed me compared to the frequent flier experience I had the first time shooting the rifle. After that first 10 round group to cure the bore coat, I let the rifle completely cool down, gave a thorough cleaning again and shot some more, slower groups to avoid heating the barrel up as much and the issue with fliers seems pretty much gone at this point. Its not the most scientific process, not every variable was controlled but to me the results are significant and worth the investment.

As far as the process, cleaning out the barrel of initial fouling or any other debris is by far the most important and time consuming step. I only used patches, never a brush but if you decide to use a brush a nylon one is recommended. I also strongly recommend using a bore guide to prevent getting your chamber all soaked, especially with the bore coat liquid.

Starting with Hoppes #9, I ran a rod through the barrel getting as much of the looser stuff out as possible. Once that was done, I used JB compound wiped generously on a patch and ran that through, sometimes letting it sit a few minutes before coming back and scrubbing it around with a dry patch. After that started coming back clean, I used Montana Extreme copper cream on a patch and ran that through the barrel as well, also letting it sit but not too long or that will damage the inside of the barrel. Scrubbed the barrel out until there was no green coming out of it, and dry patching came back clean too. Finally, finished off by running some Kroil down the barrel to really finish it off. All this was probably overkill but hopefully it did the job. If you are lucky enough to own a boreskope your job gets much easier since you can look in the barrel and tell visually when you have removed every last bit of copper fouling. I then finished the entire process by running some patches of isopropyl alcohol down the barrel to dry it out and remove any remaining solvent.

Nutshell the process: solvent -> abrasive copper remover -> chemical copper remover -> solvent -> solvent remover (isopropyl alcohol)

I repeated this process, except for the last step with alcohol, several times trying to make sure it was completely clean.

Once you have it clean the hard part is done. I used a clamp on the side of my bench to hold the rifle pointing down, and ran a loose fitting patch soaked with the bore coat down the barrel three times. Soaked and loose fitting patch are key, you want to wipe that coat onto every interior surface of the barrel. Be careful not to spill that stuff into the chamber, this is where the bore guide is super handy. If you do it should be relatively easy to remove with a brush since that part isn't going to cure super strong when you fire the gun. Remember it might be difficult to clean the chamber after the process is done because you don't want solvent finding its way into the barrel and mixing with the bore coat while its drying. You also don't want to run anything at all down the barrel between the application and firing the 10 shots to cure it. Drying period is a minimum of 6 hours I believe, hanging with the barrel pointed down. I would feel more comfortable letting it sit for a day at least.

After shooting the "curing" shots it will be a process to clean again, and you only want to use solvents. However, they state that cleaning time and number of patches required should start reducing as the compound cures and you put more shots through it and I did find that to be the case. You may not be convinced after the first 10 shots because it was still a job to clean at that point but did get easier and faster throughout the rest of the shooting.

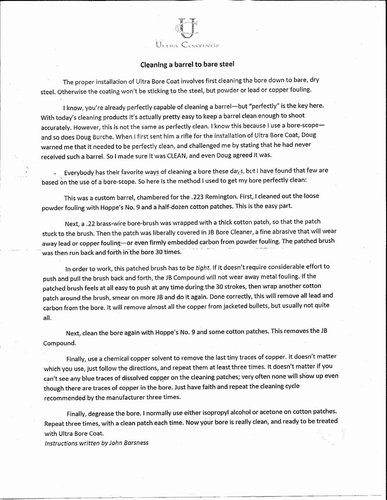

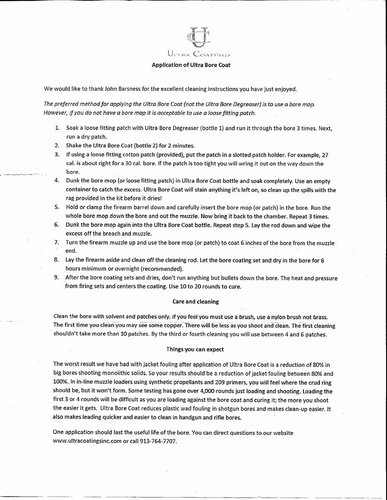

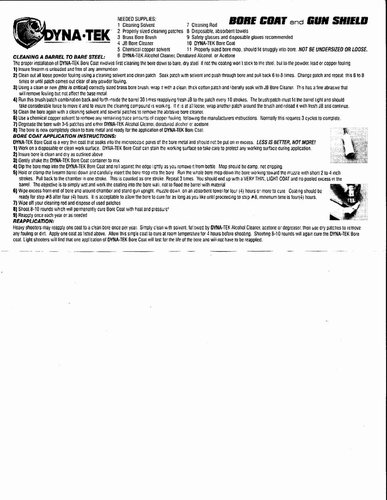

That's about it, maybe anyone with more experience (I have zero, first attempt so not an expert by any stretch) can chime in and let me know if I did anything wrong or skipped any steps. I'll attach some old copies of the instructions, when you buy it now it has some pretty vague instructions on the packaging, I found these older instructions much more helpful.

First the results. I have a Tikka 308 that was not shooting at the level I expect, and determined that copper fouling seemed to be the culprit. Dyna-tek bore coat was commonly recommended to address that issue, and after testing this weekend I do believe it helps significantly. First time out of the box at the range, I started getting fliers pretty frequently, after maybe 3 or 4 shots, shooting nosler etip lead free ammo. Yesterday was my first day at the range post bore coating and first tip, don't forget to put your bolt back into your rifle after allowing the drying period to finish or you might have to drive all the way home and all the way back before firing a shot.... not that I would know about that....

Anyways, I fired off 10 rounds per the instructions, to cure the compound in the barrel and noticed a difference pretty quickly. The very first shot was a bit wild, upper right corner of the target but every shot after that was dead nuts, about an 3 inches high at 100 yards and all nine rounds could easily be covered by a playing card. Which.. for those that shoot 10 round groups the size of a quarter at 100 yards might not be impressed, but it impressed me compared to the frequent flier experience I had the first time shooting the rifle. After that first 10 round group to cure the bore coat, I let the rifle completely cool down, gave a thorough cleaning again and shot some more, slower groups to avoid heating the barrel up as much and the issue with fliers seems pretty much gone at this point. Its not the most scientific process, not every variable was controlled but to me the results are significant and worth the investment.

As far as the process, cleaning out the barrel of initial fouling or any other debris is by far the most important and time consuming step. I only used patches, never a brush but if you decide to use a brush a nylon one is recommended. I also strongly recommend using a bore guide to prevent getting your chamber all soaked, especially with the bore coat liquid.

Starting with Hoppes #9, I ran a rod through the barrel getting as much of the looser stuff out as possible. Once that was done, I used JB compound wiped generously on a patch and ran that through, sometimes letting it sit a few minutes before coming back and scrubbing it around with a dry patch. After that started coming back clean, I used Montana Extreme copper cream on a patch and ran that through the barrel as well, also letting it sit but not too long or that will damage the inside of the barrel. Scrubbed the barrel out until there was no green coming out of it, and dry patching came back clean too. Finally, finished off by running some Kroil down the barrel to really finish it off. All this was probably overkill but hopefully it did the job. If you are lucky enough to own a boreskope your job gets much easier since you can look in the barrel and tell visually when you have removed every last bit of copper fouling. I then finished the entire process by running some patches of isopropyl alcohol down the barrel to dry it out and remove any remaining solvent.

Nutshell the process: solvent -> abrasive copper remover -> chemical copper remover -> solvent -> solvent remover (isopropyl alcohol)

I repeated this process, except for the last step with alcohol, several times trying to make sure it was completely clean.

Once you have it clean the hard part is done. I used a clamp on the side of my bench to hold the rifle pointing down, and ran a loose fitting patch soaked with the bore coat down the barrel three times. Soaked and loose fitting patch are key, you want to wipe that coat onto every interior surface of the barrel. Be careful not to spill that stuff into the chamber, this is where the bore guide is super handy. If you do it should be relatively easy to remove with a brush since that part isn't going to cure super strong when you fire the gun. Remember it might be difficult to clean the chamber after the process is done because you don't want solvent finding its way into the barrel and mixing with the bore coat while its drying. You also don't want to run anything at all down the barrel between the application and firing the 10 shots to cure it. Drying period is a minimum of 6 hours I believe, hanging with the barrel pointed down. I would feel more comfortable letting it sit for a day at least.

After shooting the "curing" shots it will be a process to clean again, and you only want to use solvents. However, they state that cleaning time and number of patches required should start reducing as the compound cures and you put more shots through it and I did find that to be the case. You may not be convinced after the first 10 shots because it was still a job to clean at that point but did get easier and faster throughout the rest of the shooting.

That's about it, maybe anyone with more experience (I have zero, first attempt so not an expert by any stretch) can chime in and let me know if I did anything wrong or skipped any steps. I'll attach some old copies of the instructions, when you buy it now it has some pretty vague instructions on the packaging, I found these older instructions much more helpful.