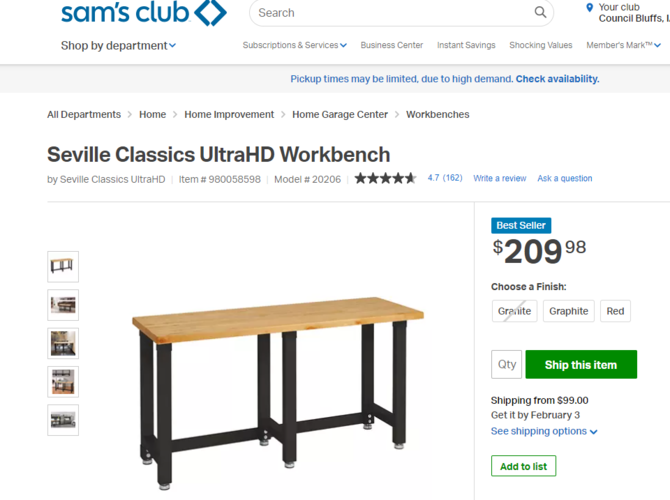

Since the move, my reloading & tinkering room has been slow to get set up. The safe is in, and there's a desk to do cleaning & other light work. I have a 4x2.5 bench to put together for stock work & other smithing activities, but I'm not sure where I want to go with the reloading bench. I'm leaning towards an 8ft by 2 foot 2x4 bench with 3/4" plywood for a top.

I need to have room for:

RCBS Rockchucker press (most centerfire rifle cartridges)

RCBS Rebel press (Black Powder cartridges)

Hornady Progressive press (pistol & a few higher volume rifle cartridges)

Brass (assume around 10K pieces)

Bullets (assume around 10K)

Tools

Trimmer

2-3 powder measures

Storage underneath for 3 tumblers, targets, some misc storage.

I've got the powder, primer & loaded ammo storage covered, just really need some good ideas on a longer bench.

I need to have room for:

RCBS Rockchucker press (most centerfire rifle cartridges)

RCBS Rebel press (Black Powder cartridges)

Hornady Progressive press (pistol & a few higher volume rifle cartridges)

Brass (assume around 10K pieces)

Bullets (assume around 10K)

Tools

Trimmer

2-3 powder measures

Storage underneath for 3 tumblers, targets, some misc storage.

I've got the powder, primer & loaded ammo storage covered, just really need some good ideas on a longer bench.