Addicting

Well-known member

I’m restoring a Remington model 24. It was my Grandfather’s and has been passed down generation to generation.

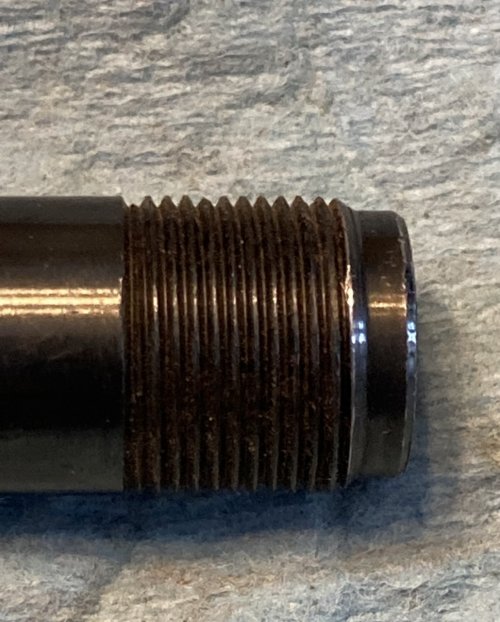

It needed a new stock and tlc after close to 100 years of use. I’m fitting the new walnut to the action and need to dry fit everything. I had to order a new magazine tube which is identical to the old one. The original was worn out and broke upon removal.

The receiver threads need to be chased as they have two bad spots in the threads. It just wants to cross thread.

The OD of the mag tube thread is .490 and it is 32 threads per inch. I cannot find anything that matches. There is a 1/2 32 available. What do I do? @p_ham

It needed a new stock and tlc after close to 100 years of use. I’m fitting the new walnut to the action and need to dry fit everything. I had to order a new magazine tube which is identical to the old one. The original was worn out and broke upon removal.

The receiver threads need to be chased as they have two bad spots in the threads. It just wants to cross thread.

The OD of the mag tube thread is .490 and it is 32 threads per inch. I cannot find anything that matches. There is a 1/2 32 available. What do I do? @p_ham

Attachments

Last edited: