Qubo

Active member

When I'm not hunting another hobby I spend way too much time/money on is 3D printing. I've printed a few things for my reloading setup and thought I would show them off and maybe also see if anyone would be interested in any of this stuff for themselves. I've got 4-5 colors now but could get just about anything. Guessing these things would be $10-$15 shipped but haven't actually looked into it.

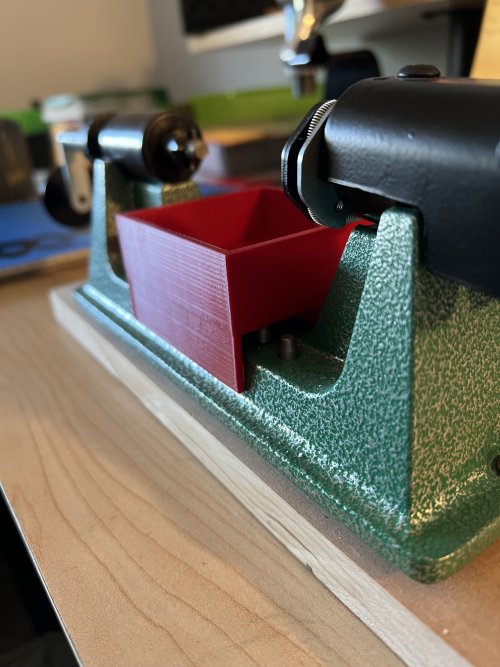

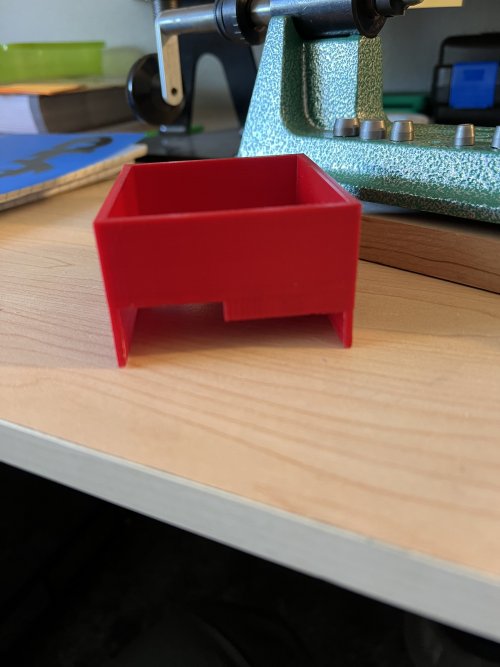

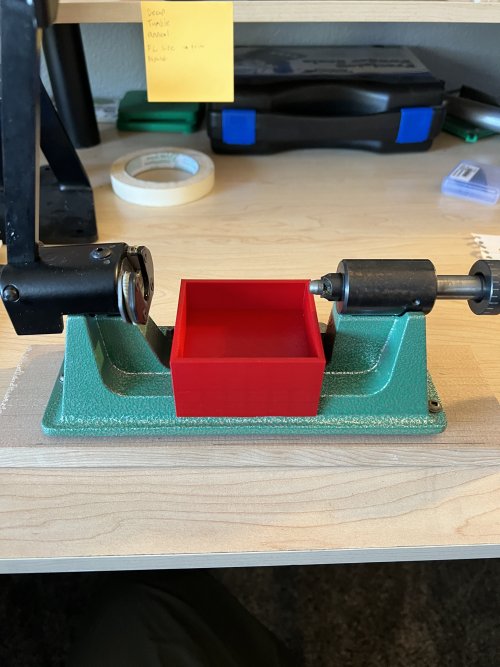

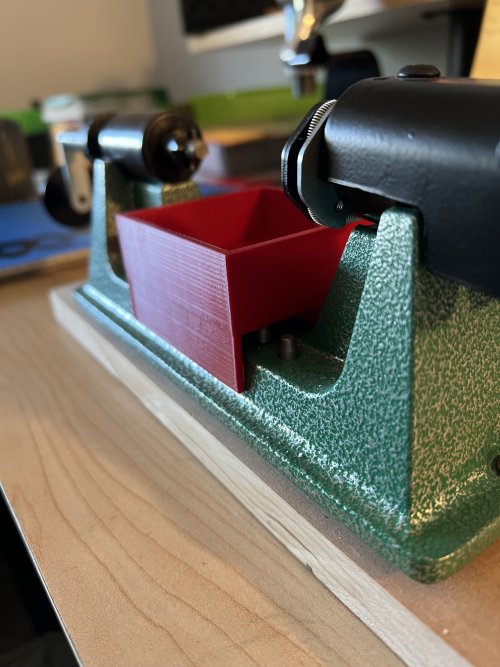

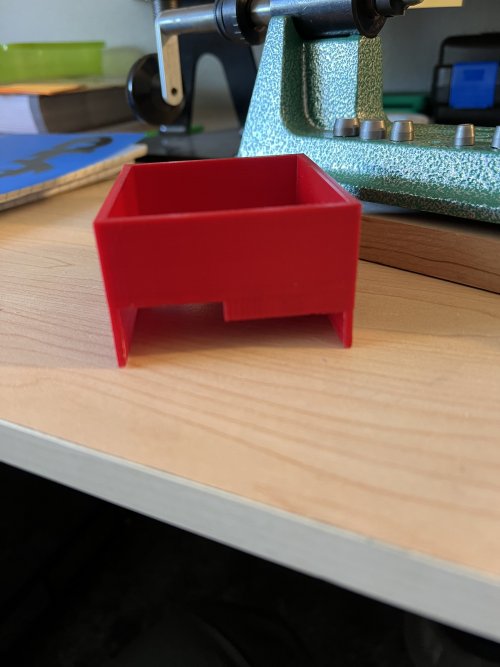

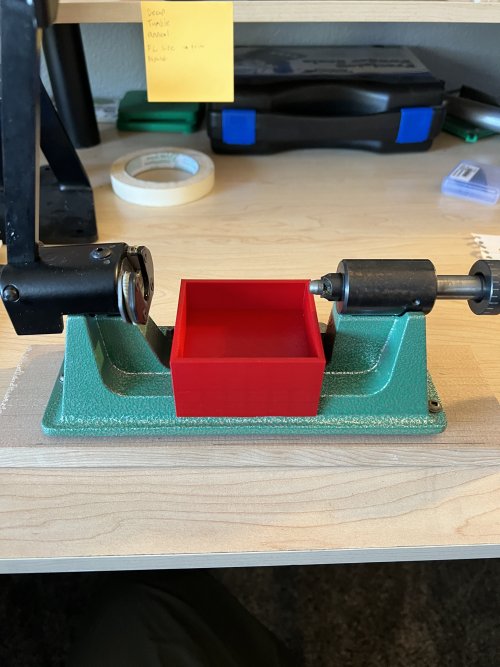

I made this catch for brass shavings on my RCBS Trim Pro 2. It just rests in the middle and is shaped on the bottom to sit on the spare collets. But I could make one that works with no spare collets.

I've made a couple reloading blocks for me and friends. I can only do 300wm, 300wsm, 9mm, and 45 cause that's all I have on hand to check the fit.

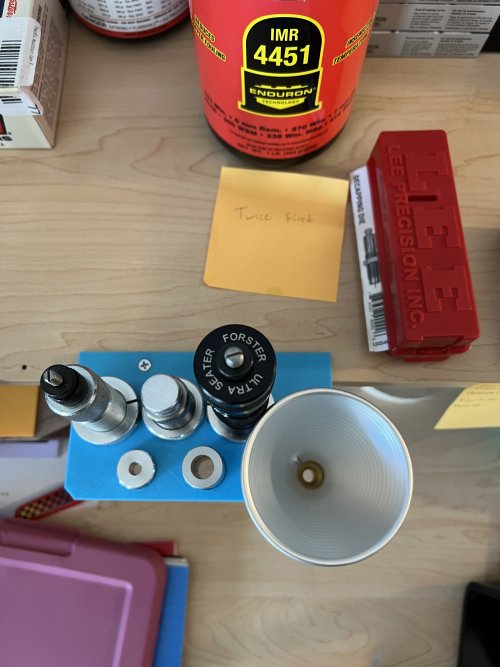

Funnel for my powder throw

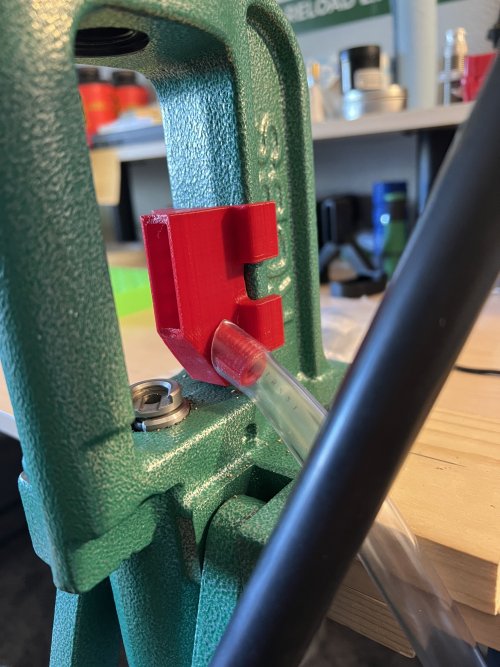

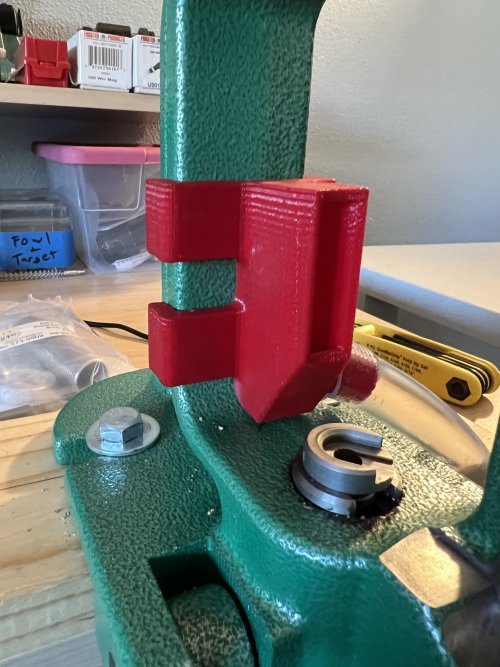

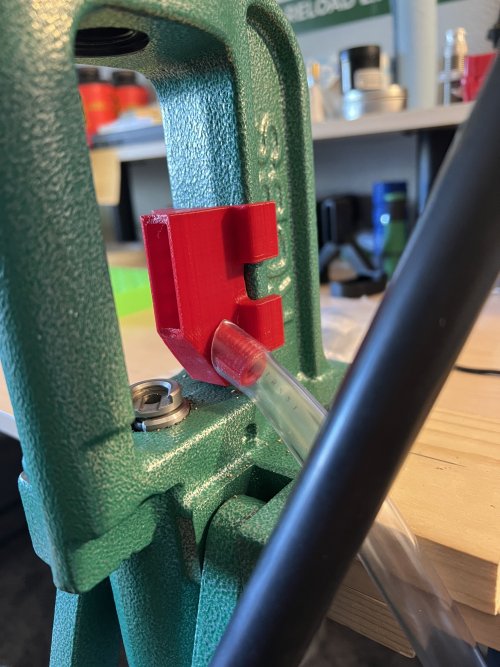

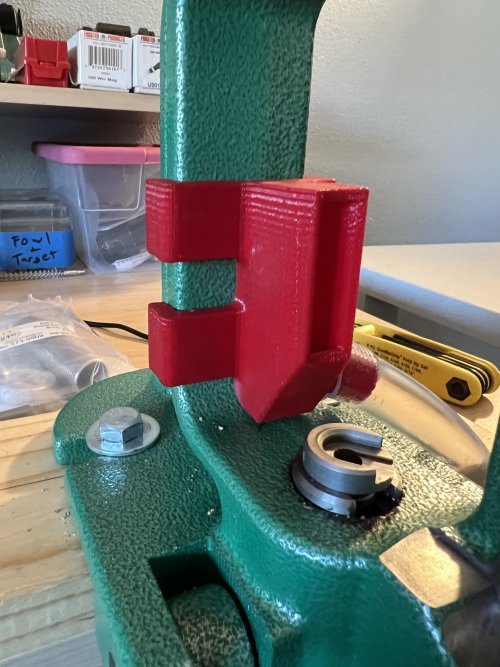

Unfortunately I can't sell next one cause it isn't my design but thought I'd show it off. It magnets on to my Rock Chucker, replaces the spent primer catch and sends primers down a tube straight into the trash. Super convenient.

Working on some other designs I'll put on here when they are done.

I made this catch for brass shavings on my RCBS Trim Pro 2. It just rests in the middle and is shaped on the bottom to sit on the spare collets. But I could make one that works with no spare collets.

I've made a couple reloading blocks for me and friends. I can only do 300wm, 300wsm, 9mm, and 45 cause that's all I have on hand to check the fit.

Funnel for my powder throw

Unfortunately I can't sell next one cause it isn't my design but thought I'd show it off. It magnets on to my Rock Chucker, replaces the spent primer catch and sends primers down a tube straight into the trash. Super convenient.

Working on some other designs I'll put on here when they are done.