p_ham

Well-known member

I wanted a softer tulip with a 1" radius at the breech but couldn't because of how the barrel was contoured prior. I'll have to look up the Hartford collars and Rigby flats. I'd like to build another rifle similar to this with some nice walnut. Might as well church it up a bit.All the wedding bands that I know of, are machined as such. But there is no reason that they could not be sweated on. Just seems like more work. Are you familiar with Hartford Collars at the breech face, or Rigby flats? That is another area where creativity can be employed. You have a pretty steep, but fairly traditional tulip at your breech face, but you could create something of your own if you wanted. Well, maybe next time anyway.

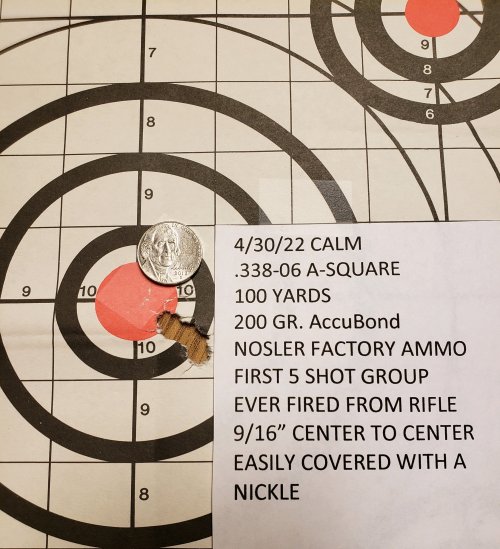

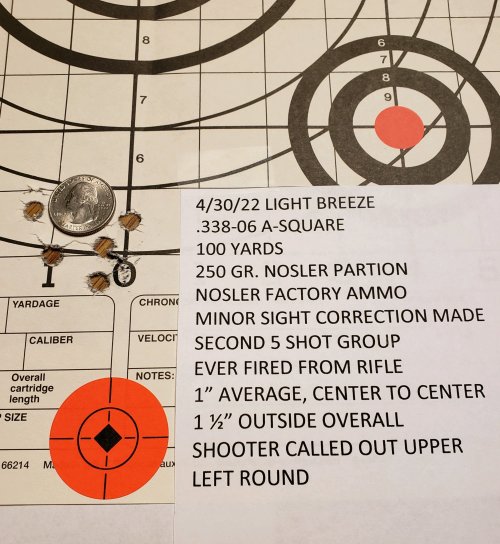

Great build so far! Can’t wait to see it finished. Are you coating it? If so what color? What bullets do you plan on shooting?

I will coat it. I'm not sure what color he wants yet. I think he said he's going to shoot 215gr partitions?