TransplantHunter

Well-known member

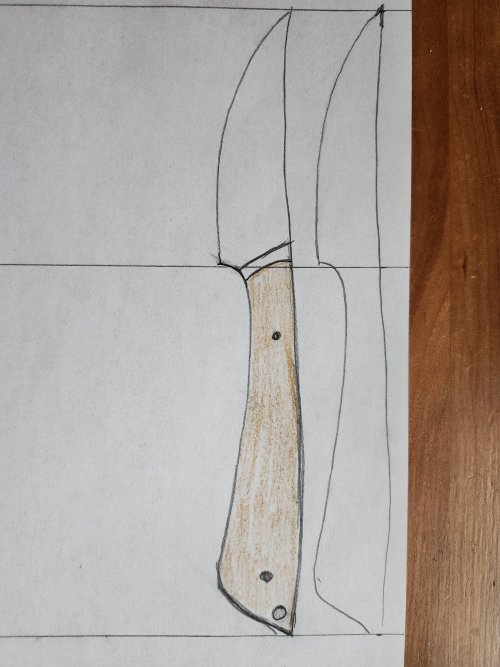

As a follow up to my last thread, I went online and found a knife that I kind of liked the looks of. Since there were no templates available (at least none that I could find), I decided to draw this one out on some paper and see what I could come up with.

Here is that drawing:

So going off that drawing, I traced it out on my bar of 1084 steel and started to cut the shape out.

After that, I got to work using some files to bring the piece down to almost its final dimensions. Once I created the bevels, I heat treated it in a stupid little loaf pan forge that I made and rested that whole contraption in a propane cylinder stove to try and keep some of the heat in. It honestly worked like a charm. Way easier to keep the heat where I wanted it during this process and was able to burn through less charcoal than my first attempt.

Once the heat treating was over, it was time to put in the elbow grease and polish this thing. After getting the tang flat by sanding it on a quartz countertop, I was able to epoxy on some walnut scales and shape it down to where I wanted it. After more and more polishing and sanding, I threw some tung oil on the handle and now I am letting it dry.

I still need to sharpen it and make a kydex sheath. I think I will work on the sheath for this knife and the first knife that I made. I kind of have been putting it off but I think I am ready to make them. All in all - I think it turned out pretty good.

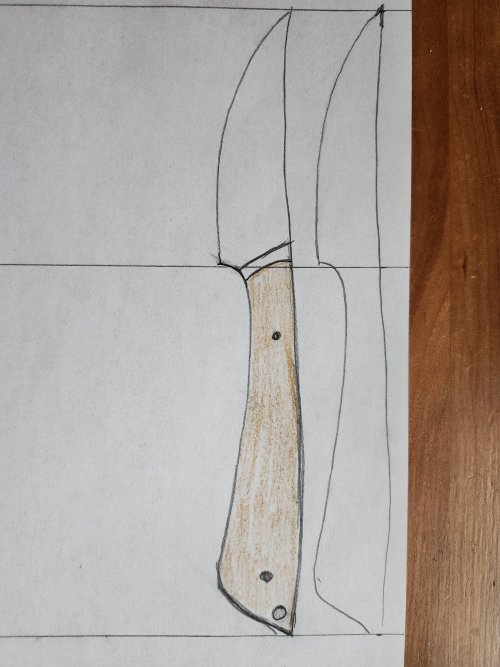

Here is that drawing:

So going off that drawing, I traced it out on my bar of 1084 steel and started to cut the shape out.

After that, I got to work using some files to bring the piece down to almost its final dimensions. Once I created the bevels, I heat treated it in a stupid little loaf pan forge that I made and rested that whole contraption in a propane cylinder stove to try and keep some of the heat in. It honestly worked like a charm. Way easier to keep the heat where I wanted it during this process and was able to burn through less charcoal than my first attempt.

Once the heat treating was over, it was time to put in the elbow grease and polish this thing. After getting the tang flat by sanding it on a quartz countertop, I was able to epoxy on some walnut scales and shape it down to where I wanted it. After more and more polishing and sanding, I threw some tung oil on the handle and now I am letting it dry.

I still need to sharpen it and make a kydex sheath. I think I will work on the sheath for this knife and the first knife that I made. I kind of have been putting it off but I think I am ready to make them. All in all - I think it turned out pretty good.