The filter sits in the compressor right where the suction valve attaches. When you remove the suction valve and look in the compressor, that filter should be sitting right there where you can pluck it out. If it's not there for some reason, get one and put it in there or you'll find yourself replacing pistons at some point.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any refrigeration guys here?

- Thread starter Redmt

- Start date

Redmt

Well-known member

Thanks. I'll get one just in case it's not there.The filter sits in the compressor right where the suction valve attaches. When you remove the suction valve and look in the compressor, that filter should be sitting right there where you can pluck it out. If it's not there for some reason, get one and put it in there or you'll find yourself replacing pistons at some point.

Redmt

Well-known member

This has been a real learning experience. I received the new low pressure suction manifold the other day and got the 404a yesterday. The first thing I noticed is the 24# cylinder is marked valve end up fo liquid charge. I've done countless automotive systems and always charge vapor. A quick Internet search says that 404 must always charge liquid because of the mixed composition of the 404 that could separate under vapor.

My questions now are, #1 after charging vapor from my nearly empty, 75# pressure remaining, is the Freon left in the cylinder not any good because of removing an incorrect mixture of gas vapor?

#2 the Internet where everything is true says to charge liquid to the high pressure side. It seems that charging liquid to the high pressure side could back feed 250# pressure back to the cylinder? Also where would the best place to charge to if it is supposed to charge liquid to the high side?

My questions now are, #1 after charging vapor from my nearly empty, 75# pressure remaining, is the Freon left in the cylinder not any good because of removing an incorrect mixture of gas vapor?

#2 the Internet where everything is true says to charge liquid to the high pressure side. It seems that charging liquid to the high pressure side could back feed 250# pressure back to the cylinder? Also where would the best place to charge to if it is supposed to charge liquid to the high side?

It's always good to learn! The basics are universally applicable but the actual systems vary enough that there's always room to learn something new, even if you've been at it for 30+ years.

Did you ever get to spraying soapy water on connections? Replacing the suction valve and recharging won't fix the issue if the leak is somewhere else. There's also the issue that recharging is going to be tricky and risky. I'll explain why in a second.

Before we get into charging the system, did you already change the valve? How did you do it? Did you vacuum out the low side and the compressor? I'd like to know what has been done there before we move forward.

Did you ever get to spraying soapy water on connections? Replacing the suction valve and recharging won't fix the issue if the leak is somewhere else. There's also the issue that recharging is going to be tricky and risky. I'll explain why in a second.

Before we get into charging the system, did you already change the valve? How did you do it? Did you vacuum out the low side and the compressor? I'd like to know what has been done there before we move forward.

Redmt

Well-known member

I did check for leaks with super bubbly soap, all clear. I haven't touched any else yet. My plan was to run a vacuum test before changing anything to see what happens. IF! There's no leaks, I was going to change the suction valve and retest just in case I created one.

I figured I would wait and see what your next instructions were. We are supposed to ia couple reasonably cooler days next week. I'm in no monster hurry so a day or week or so isn't going to hurt.

I figured I would wait and see what your next instructions were. We are supposed to ia couple reasonably cooler days next week. I'm in no monster hurry so a day or week or so isn't going to hurt.

Ah, understood. Ok, first, you are correct that charging from the high side is going to be difficult due to the pressure difference. That gives us one other option.

But before that, here's what I recommend for changing the valve itself:

Step 1: Close receiver outlet valve.

Step 2: Let system run until it shuts itself off at low suction cutoff point.

Step 2A: Turn off power, and close discharge service valve.

Step 3: Recover freon from just the low side

Step 4: Remove all fittings from suction service valve

Step 5: Unbolt suction service valve

Step 6: Clean surface thoroughly (regular scouring pad should work)

Step 7: Put on new valve gasket and valve, and bolt it down

Step 8: Reattach all the lines

Step 9: Evacuate low side of system

Step 9A: Open discharge service valve (back seat)

Step 10: Open your receiver outlet valve (make sure it's fully evacuated)

Step 10A: Turn power back on

Step 11: Let system run

Step 12 (if needed): Slowly add liquid freon to low side. Very slowly, around 1 ounce per minute. Only do this if the system is low, if it's still good from your last recharge, you shouldn't have to do this.

Questions from me: Does your system have a high pressure cutoff switch? If so, where is the sensor line located?

But before that, here's what I recommend for changing the valve itself:

Step 1: Close receiver outlet valve.

Step 2: Let system run until it shuts itself off at low suction cutoff point.

Step 2A: Turn off power, and close discharge service valve.

Step 3: Recover freon from just the low side

Step 4: Remove all fittings from suction service valve

Step 5: Unbolt suction service valve

Step 6: Clean surface thoroughly (regular scouring pad should work)

Step 7: Put on new valve gasket and valve, and bolt it down

Step 8: Reattach all the lines

Step 9: Evacuate low side of system

Step 9A: Open discharge service valve (back seat)

Step 10: Open your receiver outlet valve (make sure it's fully evacuated)

Step 10A: Turn power back on

Step 11: Let system run

Step 12 (if needed): Slowly add liquid freon to low side. Very slowly, around 1 ounce per minute. Only do this if the system is low, if it's still good from your last recharge, you shouldn't have to do this.

Questions from me: Does your system have a high pressure cutoff switch? If so, where is the sensor line located?

Redmt

Well-known member

I'm going to have to read this over several times to make sure I understand what is where. I understand what we're doing, we're going to split the system from the high side to the low as to not loose much Freon correct? I will have to properly identify which connection fittings are which first.

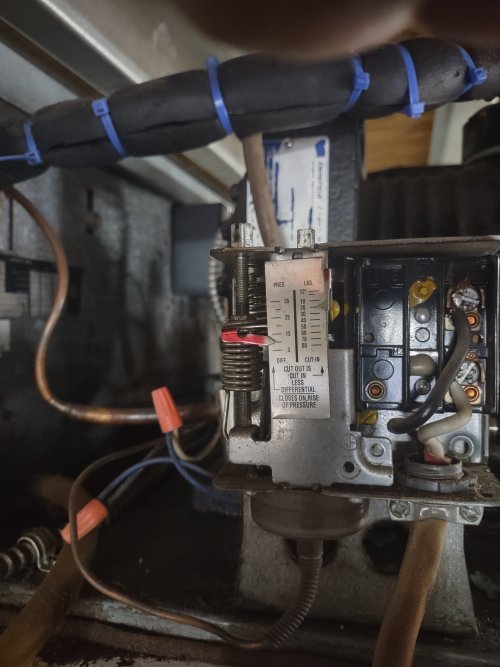

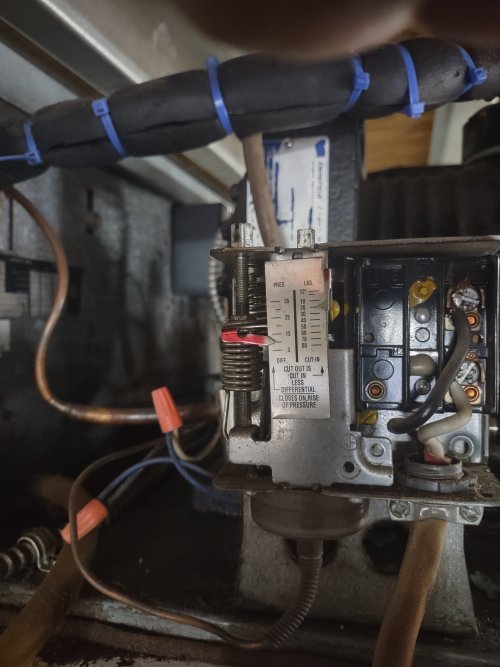

Now, the low pressure manifold that I'm replacing is stuck open. There's a small line coming off of it to the square grey box in post #10.

Next question is to existing Freon mixture. The system has been charged with vapor and not liquid. Will the vapor charge have screwed up the balance of Freon mixture from day one? I have no issues with purging and vacuum testing the entire system. At this point the cost of Freon doesn't matter. I have a 24# cylinder!!

Now, the low pressure manifold that I'm replacing is stuck open. There's a small line coming off of it to the square grey box in post #10.

Next question is to existing Freon mixture. The system has been charged with vapor and not liquid. Will the vapor charge have screwed up the balance of Freon mixture from day one? I have no issues with purging and vacuum testing the entire system. At this point the cost of Freon doesn't matter. I have a 24# cylinder!!

No, we are not splitting the system from high to low, we are splitting from low to high.

There is a possibility that charging with just vapor may have upset the balance of freon mixture, but it's hard to say from my end. Probably not too much, because the system was running at the temperature you wanted.

Shouldn't have to remove all the freon in there now. But ultimately that will be up to you if it gives you ease of mind after you replace the valve.

There is a possibility that charging with just vapor may have upset the balance of freon mixture, but it's hard to say from my end. Probably not too much, because the system was running at the temperature you wanted.

Shouldn't have to remove all the freon in there now. But ultimately that will be up to you if it gives you ease of mind after you replace the valve.

Redmt

Well-known member

I finally got everything together and working. My problem is that the temperature differential is too  high. I'm at 8*. Pressures are 220 high side and 30 low side. Compressor off is 10-180. It cycles from 8* to 23.9. This is the pressure switch that activates the solenoid for Freon flow. It doesn't seem to matter where I set the thermostat, the differential is always pretty close to the same. I don't see an adjustment on the thermostat for temp differential. How should the pressure switch be set?

high. I'm at 8*. Pressures are 220 high side and 30 low side. Compressor off is 10-180. It cycles from 8* to 23.9. This is the pressure switch that activates the solenoid for Freon flow. It doesn't seem to matter where I set the thermostat, the differential is always pretty close to the same. I don't see an adjustment on the thermostat for temp differential. How should the pressure switch be set?

high. I'm at 8*. Pressures are 220 high side and 30 low side. Compressor off is 10-180. It cycles from 8* to 23.9. This is the pressure switch that activates the solenoid for Freon flow. It doesn't seem to matter where I set the thermostat, the differential is always pretty close to the same. I don't see an adjustment on the thermostat for temp differential. How should the pressure switch be set?

high. I'm at 8*. Pressures are 220 high side and 30 low side. Compressor off is 10-180. It cycles from 8* to 23.9. This is the pressure switch that activates the solenoid for Freon flow. It doesn't seem to matter where I set the thermostat, the differential is always pretty close to the same. I don't see an adjustment on the thermostat for temp differential. How should the pressure switch be set?Similar threads

- Replies

- 0

- Views

- 325

- Replies

- 27

- Views

- 2K